Shell mold casting, in that molten metal is poured into an expendable mold. the mold is a thin-walled shell created from applying a sand-resin mixture around a pattern. The pattern, a metal piece in the shape of the desired part, is reused to form multiple shell molds. A reusable pattern allows for higher production rates, while the disposable molds enable complex geometries to be cast.

The materials that can be used with this process are cast irons, and aluminum and copper alloys. Typical parts are small-to-medium in size and require high accuracy, such as gear housings, cylinder heads, connecting rods, and lever arms.

Benefits of Shell Mold Casting:

1.Shell molding process offers better dimensional tolerances

2.Shell molding process offers better surface finish.

3. Shell Molding Process offers higher throughput due to reduced cycle times.

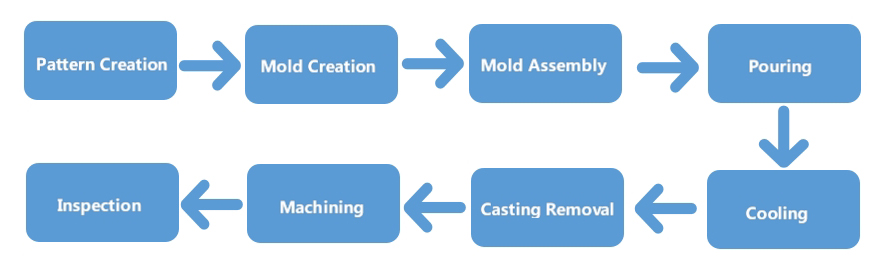

The Process of Shell Mold Casting

Cassie

Cassie

Sales Manager

Sales Manager